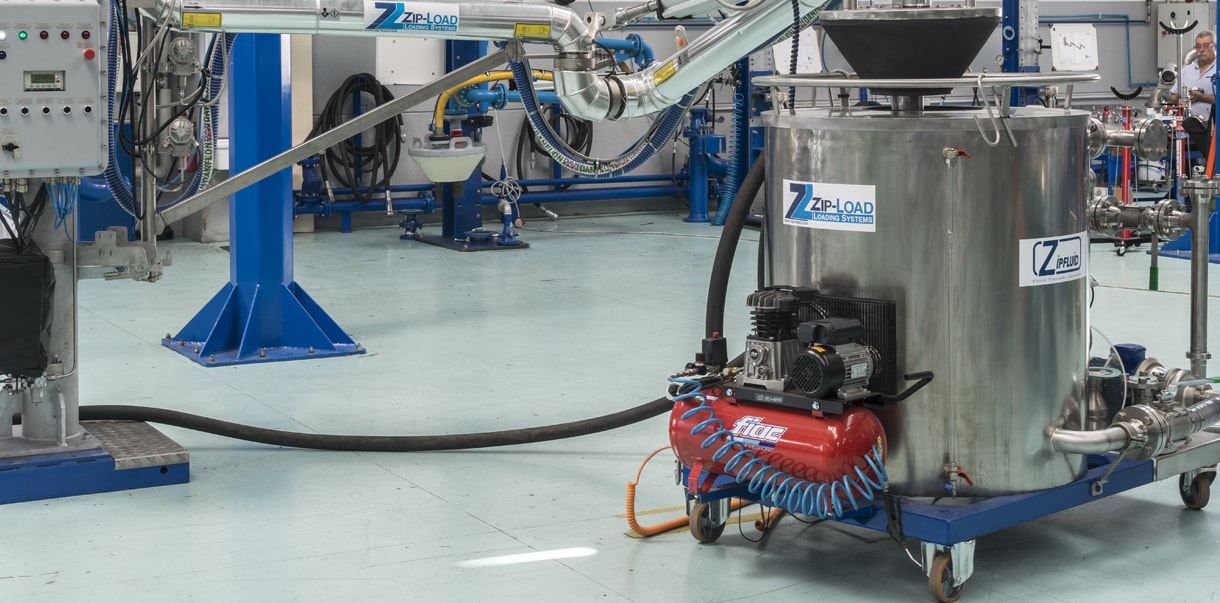

Il nostro reparto produttivo ha sede in un moderno edificio industriale, dove i nostri prodotti vengono assemblati e testati prima di essere consegnati alla destinazione finale.

Il nostro approccio produttivo è estremamente flessibile e spazia dal Build to Stock all’Engineering to Order, consentendo sia tempi di consegna brevi – nel caso di prodotti standard – che piani di fornitura ad hoc – nel caso di progetti altamente personalizzati.

Le attrezzature e i processi di stampaggio, saldatura e verniciatura vengono eseguiti in conformità alle “best practices” mondiali e a tutte le norme EN, ASME e ISO International Standards applicabili, grazie alla professionalità del nostro staff tecnico qualificato.

A seconda delle modalità di trasporto e delle condizioni di stoccaggio, il cliente può scegliere tra diversi standard di imballaggio, che sono in grado di garantire uno stoccaggio a lungo termine – fino a 48 mesi – anche nelle più difficili condizioni ambientali, in presenza di pioggia, polvere, umidità o atmosfera salina.

In caso di spedizione Extra-UE, il nostro Magazzino Doganale consente di velocizzare tutte le procedure di esportazione e quindi la consegna della merce alla destinazione finale.