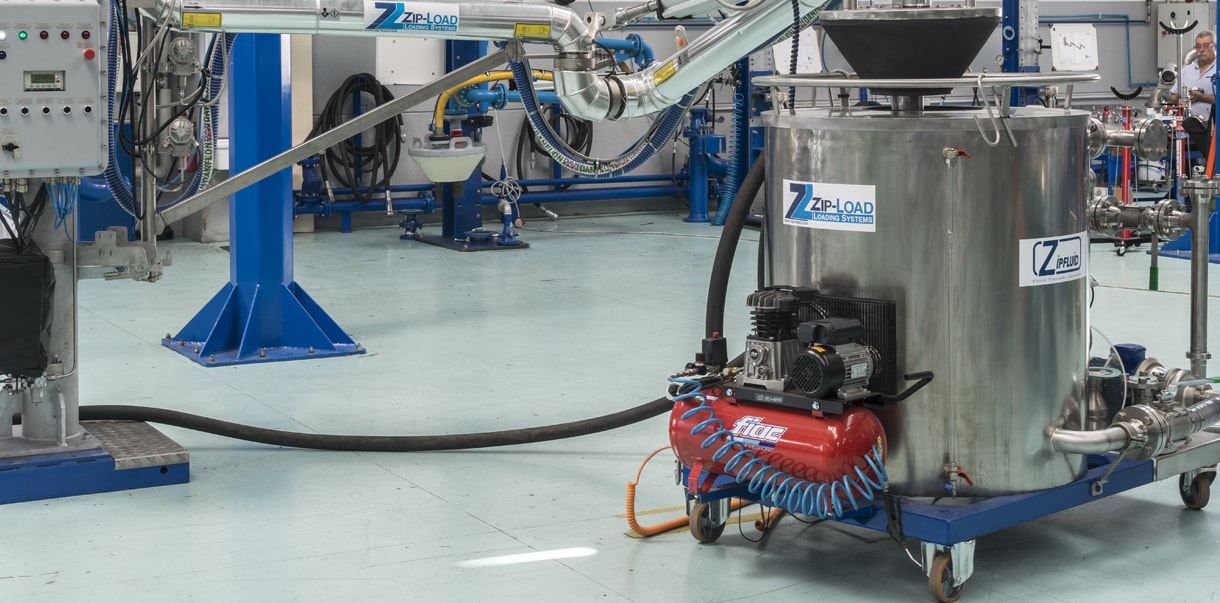

Zipfluid Factory is established in a modern industrial building, where our products are welded, assembled and tested, before being delivered to the final destination.

Our manufacturing approaches range from “Build to Stock” to ”Engineering to Order”, allowing a short lead time in case of standard products, and flexible Supply Chain Management in case of highly customized projects.

Thanks to our certified technical staff, the tooling, welding and painting processes are performed in accordance with world class practice and comply with all applicable EN, ASME and ISO International Standards.

As far as EU Directives and Regulations are concerned, we comply with 2014/34 (ATEX), 2014/68 (PED), 2006/42 (Machinery), 2014/35 (Low Voltage), 2014/30 (EMC) and 2004/1935 (Food).

Our customers can choose, according to the type of transport and storage conditions, among several different packing types. Our packing options ensure a long-term storage – up to 48 months – even in case of harsh environmental conditions, such as rain, dust, moisture and salty air.

In case of export to Non-EU countries, our internal Bonded Warehouse allows for expediting customs procedures and consequently speeding up delivery of the goods to the final destination.