This type of loading arm is a system that allow operators to work in safe conditions at ground level (i.e: no need to stay on top of the tanker) during loading.

These arms are designed to load /unload liquids or gas on/from road or rail tankers with flange connection or via a coupling where vapour return is necessary.

The possibility to choose a bottom loading/unloading arm instead of a top loading arm, depends on whether the tanker is equipped with a built-in overfill sensor.

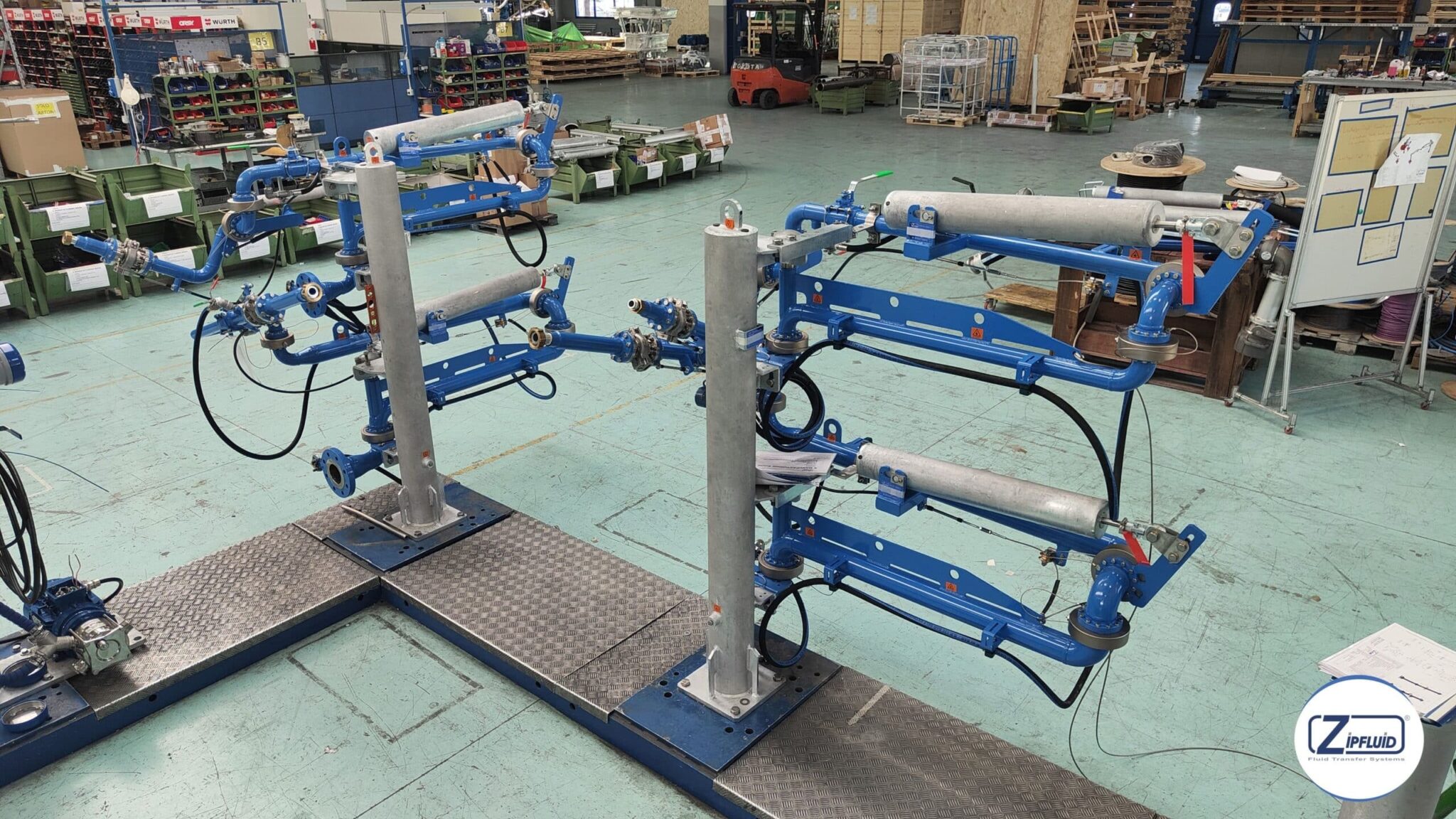

All Zipfluid bottom loading arms are endowed with a break-away valve: in many countries, the use of this type of valve is already compulsory as a mean to avoid loss of liquid, if the tanker makes an unplanned departure, by a mistake or by oversight, before loading/unloading is completed.

Manual actuation of the Zipfluid arms is very simple, thanks to use of high-quality swivels (up to six per arm) and to the accuracy of the balancing systems.

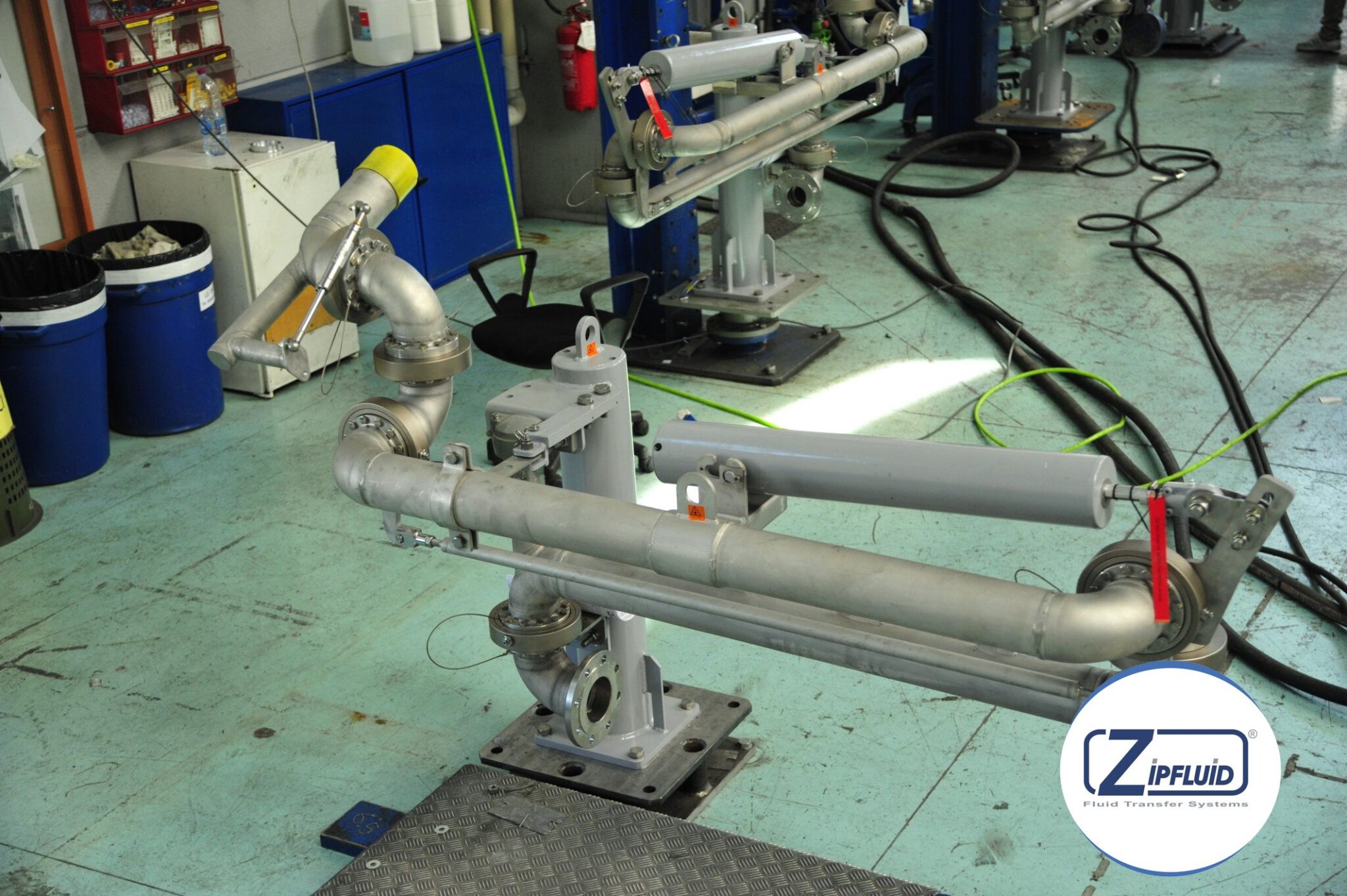

LA210 SERIES Bottom loading arm

Bottom Loading Arms are articulated, self-supported pipelines used to transfer fluids from stocking depots to road or railway tankers while standing on the ground, frequently through an API RP 1004 valve.

LA210 series is compression spring balanced, with flexible vertical arm.

- Standards and Regulation

- Technical specifications

- Components description (standard version)

- Options

- Accessories

- Manual

- 94/9/EC Directive (ATEX)

- 2006/42/EC Directive (Machinery)

- 97/23/EC Directive (PED)

- ASTM – ANSI – TTMA Standards

- Design temperature: -15 / +65°C

- Design pressure: 10 bar

- Test pressure: 15 bar

- Flow rate @ 6m/s:

- 3” > 82 m3/h

- 4” > 150 m3/h

- Right hand layout, bottom inlet, ANSI150 inlet flange

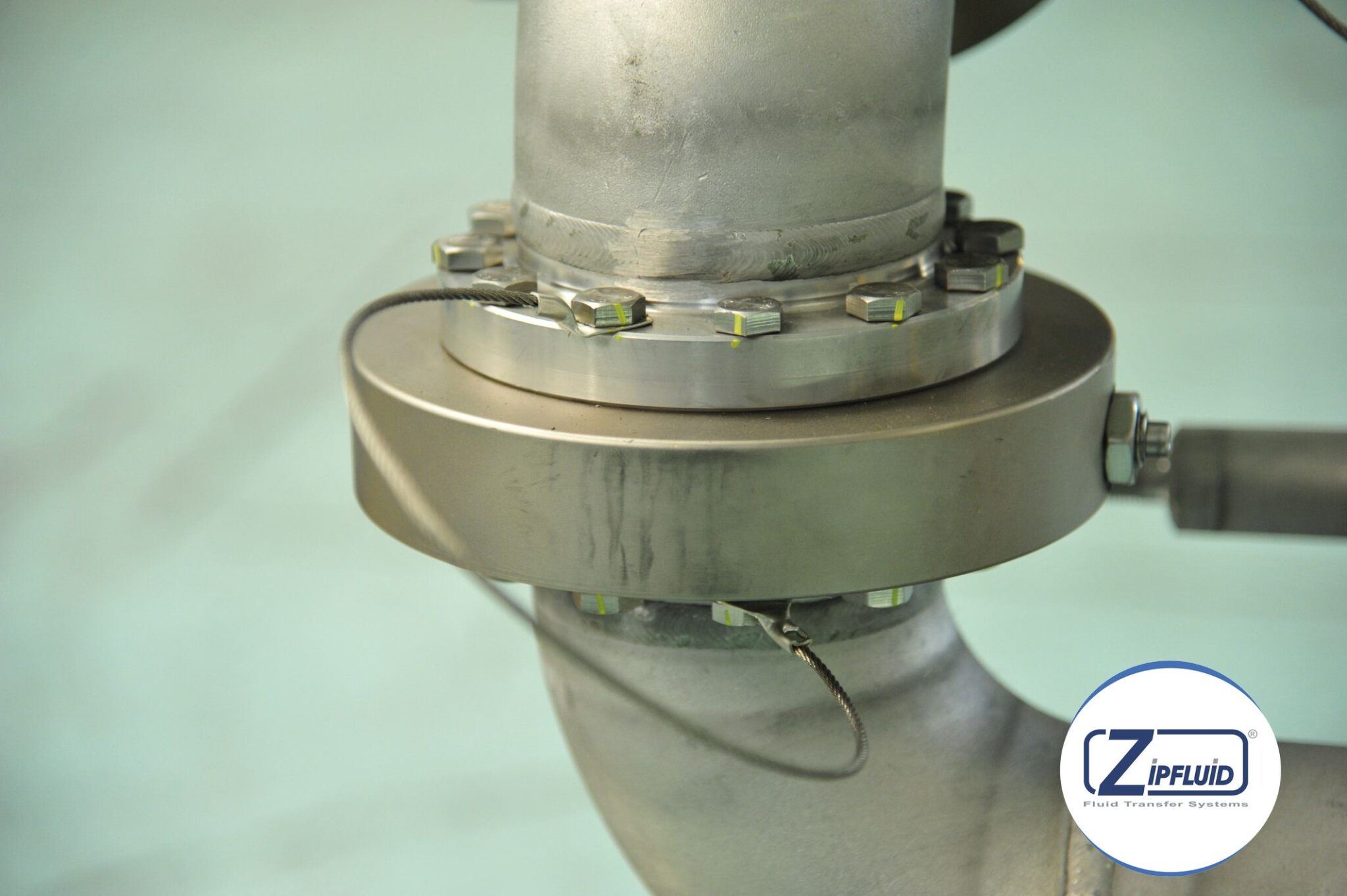

- Double base swivel style F-50 in carbon steel + FKM seals

- Compression spring balancing unit

- Primary pipe in carbon steel

- Swivel style F-40 in aluminum alloy + FKM seals

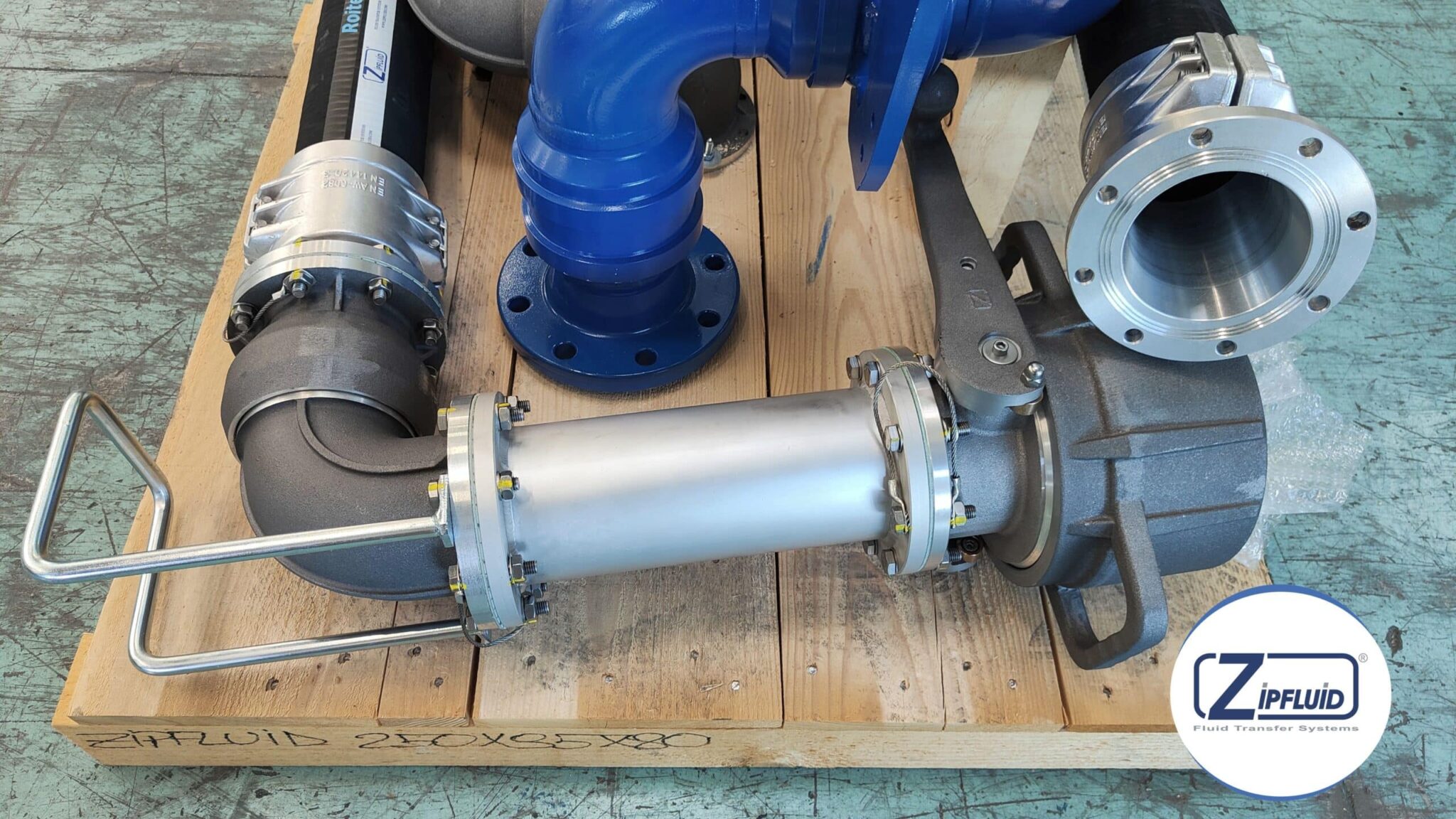

- Vertical flexible hose, conductive type, according to EN 12115

- Swivel style F-30 in aluminum alloy + FKM seals, with handle

- 4” API RP 1004 dry break coupler in aluminum alloy + FKM seals

- Different pipes length

- Diameters: from 3” to 4” long reach version

- Other materials: CS – KCS – SS

- Other seals: HNBR – FFKM – PTFE – VMFQ

- Base flange: PN16 or other standards

- Layout: Left-hand

- Inlet: Top vertical

- Split type swivels

- Rigid vertical tube with double ending swivel

- Special configurations for extended temperature (-60/+200 °C)

- Vapour recovery version, with vapor recovery coupler API RP1004

- Semi-automatic coupler

- Stanag 3756 hose unit coupler

- Jet fuel version, with hose EN1825 type C

- Custom color coding

- Coupler switch

- E mergency release valve

- Back-check valve

- Parking device

- Parking switch

- Sight glass

- Stainless steel protection sleeve for flexible hose

- Standpost