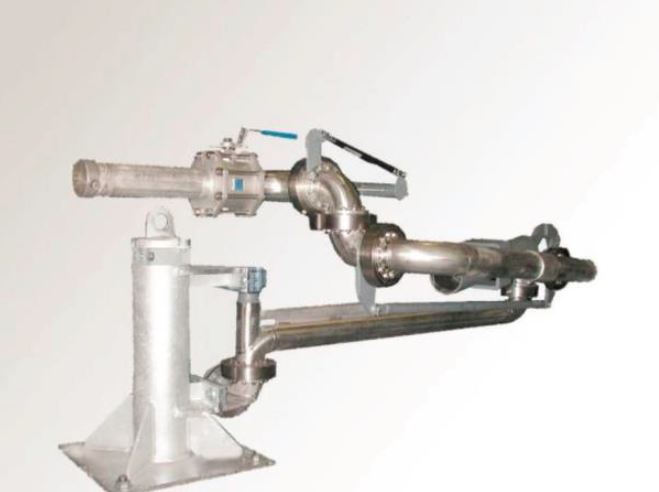

Operation & process Loading & Unloading Arms They require only one operator to use Equipped with process valves and couplers Equipped with purge and drainage valves Equipped with heating and insulation system Equipped with process sensors and control panel with load interlock management Side and rear connection to tanks

Operation & process Hoses May require multiple operators to use

Difficult to equip with process valves due to the unsupported weight

Difficult to fit with purge and drain valves due to the weight involved

They may have product stagnation in the curves

Difficult to equip with heating systems and process sensors

Operator safety Loading & Unloading Arms Jointed for easy handling

Self-supported by the balancer – no effort on the part of the operator

Parking safely and neatly to avoid tripping

They allow to have safe maneuvering points, not contaminated by the transferred product

Operator safety Hoses Heavy to handle

Placed on the ground, which obstruct the passage with the risk of tripping

They may have product spills during use with consequent risk of contact with the operator

Risk of major accidents (Seveso) Loading & Unloading Arms Equipped with various types of emergency release valves in case of accidental starting of the tanker

Equipped with double safety sealing systems

Equipped with leak detection system

Equipped with process sensors and control panel with safety interlock management

From specialized literature, the arms have a leak rate ten times lower than that of the hoses

From specialized literature, the booms have a serious failure rate ten times lower than that of hoses

Possible achievement of failure conditions configurable as not reasonably conceivable (𝟏𝟎−𝟖 𝟏𝟎−𝟗) with consequent reduction in insurance costs

Risk of major accidents (Seveso) Hoses Equipped only with cable emergency release valve

They may have serious breakages (therefore with large fluid spills) due to the accidental departure of the tanker

They can have serious losses or breakages because they are placed on the ground, tangled, crushed by the tanker, etc.

Maintenance Loading & Unloading Arms Swivel joints with permanent lubrication

Four-piece swivel joints for easy maintenance

Preventive maintenance (seals replacement) approximately every 15,000 cycles (depending on the application)

Warranty extendable to five years

Dedicated preventive / extraordinary maintenance contracts

Maintenance Hoses Annual pressure test

Ordinary maintenance

Life Cycle Cost Loading & Unloading Arms Indicatively (depending on the application) 25 years of guaranteed useful life

Possibility of not supervising the loading point using the leak detection and automatic loading systems with the consequent possibility of reallocating human resources

Life Cycle Cost Hoses Indicatively (depending on the application) 5 years of useful life